Contractors

Labor and Time-Saving Metal-over-Metal Retrofit Solutions for Building Contractors

Roof Hugger’s metal-over-metal retrofit systems are the ideal application when an old outdated metal roof needs to be replaced. This environmentally friendly option allows the existing metal roof to remain, the new metal roof installed directly over the old roof providing a safe and labor-saving installation

Contractors

Labor and Time-Saving Metal-over-Metal Retrofit Solutions for Building Contractors

Roof Hugger’s metal-over-metal retrofit systems are the ideal application when an old outdated metal roof needs to be replaced. This environmentally friendly option allows the existing metal roof to remain, the new metal roof installed directly over the old roof providing a safe and labor-saving installation

Roof Hugger Applications

Roof Hugger’s versatile products were initially designed for re-roofing existing metal buildings. They are also suitable for new construction requiring an air-space cavity between a new metal roof and a sub-deck for energy efficiency and solar thermal systems, with the ability to customize according to the cavity depth and air flow needed.

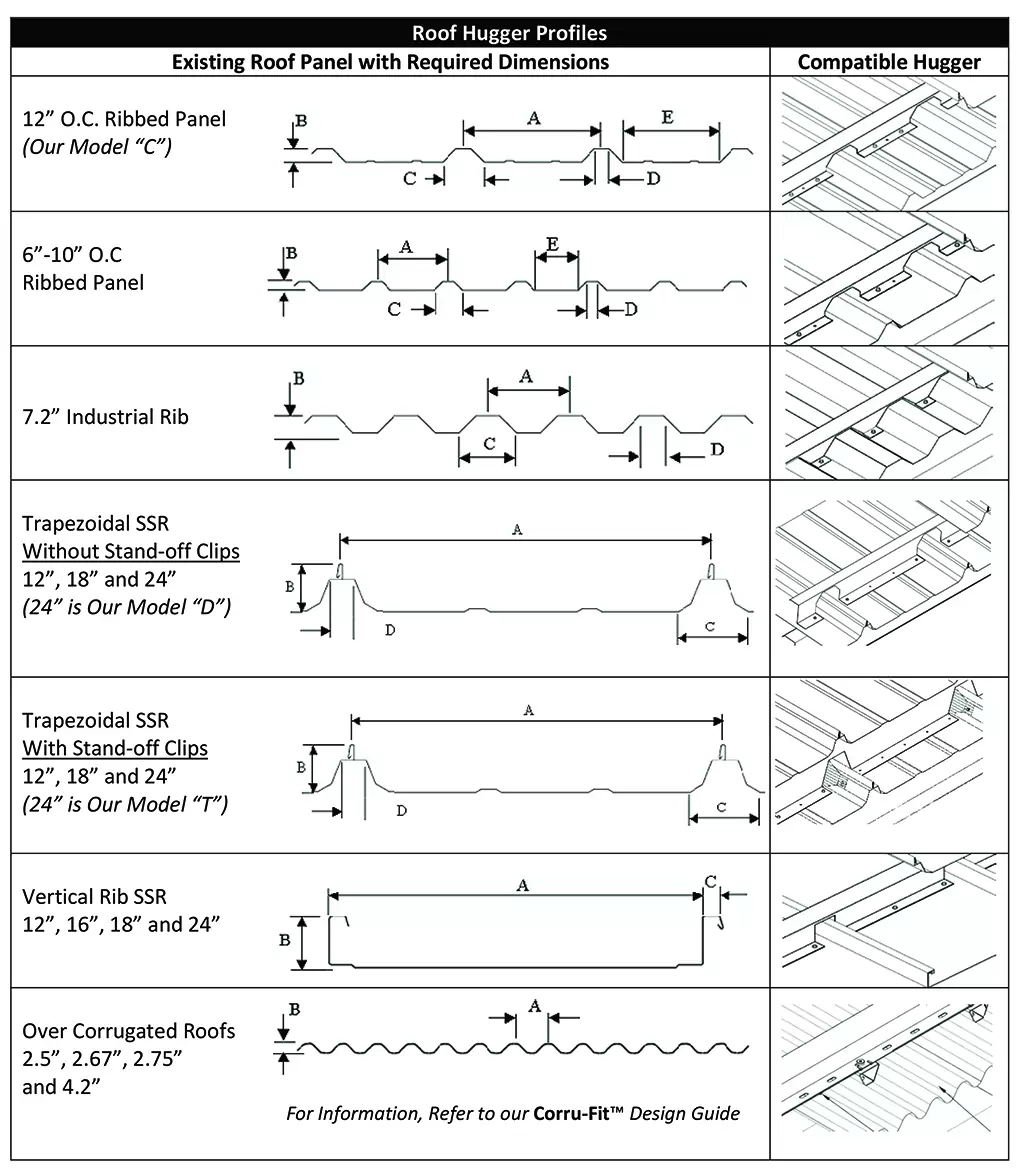

The most common Hugger profiles for retrofitting existing metal roofs are shown in the profile image.

If your project requires a profile not listed here, we can accommodate it with the physical dimensions of your existing roof.

Product Details

Existing or Thru-Fastened Panel Group

Roof Huggers are designed to fit over Thru-Fastened panels, from our standard Model C which fits a typical 12″ on center panel with a ;max rib height of 1.5 x 4″ wide base to our Custom Parts.

| Existing Expansion Joint – Generic | Hugger Attachment- Trapezoidal SSR over R-Panel | Rake End Wall- Trapezoidal SSR over R-Panel |

|---|---|---|

| High Eave Non Vented- Generic | Hugger Attachment- Vertical SSR over R-Panel | Rake End Wall- Vertical SSR over R-Panel |

| High Eave Vented- Generic | Lean To Step Detail- Generic | Rake to Wall- Trapezoidal SSR over R-Panel |

| High Eave- R-Panel over R-Panel | Low Eave- R-Panel over R-Panel | Rake to Wall- Vertical SSR over R-Panel |

| High Eave- Trapezoidal SSR over R-Panel | Low Eave- Trapezoidal SSR over R-Panel | Ridge Detail- Non Vented- Generic |

| High Eave- Vertical SSR over R-Panel | Low Eave- Vertical SSR over R-Panel | Ridge Detail- Vented- Generic |

| Hugger Lap Attachment – Standard R-Panel | Panel Fixity- Hugger w Hat on Hat-R-Panel | Valley Cross Section- Generic |

| Hugger Attachment- Custom- Trapezoidal SSR over 6”-10″ R-Panel | Panel Fixity- Model-C w Integral SubRafter Hat | Valley Gutter- Generic |

| Hugger Attachment- Custom- Vertical SSR over 7.2 Rib Panel | Pitch Break- Roof to Wall- Generic | Zone Grid Framing- Hugger Custom w Hat on Hat |

| Hugger Attachment- R-Panel over R-Panel | Rake End Wall- R-Panel over R-Panel | Zone Grid Framing- Model C w Integral Sub Rafters |

Existing 24″ on Center Trapezodial SSR Roof Panel Installed on Low Clips

Roof Huggers are designed to fit over the Trapezoidal SSR panel, from our standard Model D which fits a typical 24” on center panel with a max rib height of 3”, to our Custom Parts that can be fabricated to fit over any rib spacing Trapezoidal Panel from 12”oc to 30” oc rib spacing, any rib height, and any custom height up to 10”.

| Generic – Existing Expansion Joint | Generic – Valley Cross Section | Trapezoidal SSR over Trapezoidal SSR – Rake to Wall |

|---|---|---|

| Generic – High Eave Non Vented | Generic – Valley Gutter | Vertical SSR over Trapezoidal SSR – High Eave |

| Generic – High Eave Vented | Trapezoidal SSR – Huggers w Hat on Hat- Panel Fixity | Vertical SSR over Trapezoidal SSR – Hugger Attachment |

| Generic – Hip Cross Section | Trapezoidal SSR – Huggers w Hat on Hat- Zone Grid | Vertical SSR over Trapezoidal SSR – Low Eave |

| Generic – Hugger Attachment Detail | Trapezoidal SSR over Trapezoidal SSR – High Eave | Vertical SSR over Trapezoidal SSR – Rake to Wall |

| Generic – Hugger Lap Attachment | Trapezoidal SSR over Trapezoidal SSR – Hugger Attachment | Vertical SSR over Trapezoidal SSR – Rake End Wall |

| Generic – Ridge Detail- Non Vented | Trapezoidal SSR over Trapezoidal SSR – Low Eave | |

| Generic – Ridge Detail- Vented | Trapezoidal SSR over Trapezoidal SSR – Rake End Wall |

Existing 24” On Center Trapezoidal SSR Roof Panel Installed on Tall/Standoff Clips, and Thermal Blocks or structural decking with rigid insulation over.

This specially designed Roof Hugger is to be used with existing Trapezoidal SSR roof panels that are installed on Tall/Standoff Clips or structural decking with rigid insulation over. Our standard Model T fits a typical 24” on center panel with a max rib height of 3”, or you may need a Custom Part that can be fabricated to fit over any rib spacing Trapezoidal SSR Panel from 12”oc to 30” oc rib spacing, any rib height and any custom height up to 10”.

| Generic – Existing Expansion Joint | Generic – Valley Cross Section | Trapezoidal SSR over Trapezoidal SSR – Rake End Wall |

|---|---|---|

| Generic – High Eave Vented | Generic – Valley Gutter | Trapezoidal SSR over Trapezoidal SSR – Rake to Wall |

| Generic – Hip Cross Section | Generic – High Eave Non Vented | Vertical SSR over Trapezoidal SSR – High Eave |

| Generic – Hugger Attachment Detail | Trapezoidal SSR – Huggers w Tabs & Hat on Hat- Zone Grid | Vertical SSR over Trapezoidal SSR – Hugger w Tab Attachment |

| Generic – Hugger Lap Attachment | Trapezoidal SSR – Huggers w Hat on Hat- Panel Fixity | Vertical SSR over Trapezoidal SSR – Low Eave |

| Generic – Lean To Step Detail | Trapezoidal SSR over Trapezoidal SSR – High Eave | Vertical SSR over Trapezoidal SSR – Rake End Wall |

| Generic – Ridge Detail- Non Vented | Trapezoidal SSR over Trapezoidal SSR – Hugger w Tab Attachment | Vertical SSR over Trapezoidal SSR – Rake to Wall |

| Generic – Ridge Detail- Vented | Trapezoidal SSR over Trapezoidal SSR – Low Eave |

Existing Vertical Rib Standing Seam Roof Panel with Various On Center Rib Spacing From 12” to 30”

Roof Huggers are designed to fit over existing Vertical Rib panel types. Our Custom 2.75” Huggers can be fabricated to fit over any rib spacing Vertical Rib Panel from 12”oc to 30” oc rib spacing, any rib height and any custom height up to 10”. They are also available for Vertical Rib Systems that are installed with Standoff Clips

| Generic- Existing Expansion Joint | Generic- Valley Gutter Detail | Vertical SSR over Vertical SSR- High Eave |

|---|---|---|

| Generic- High Eave – Non Vented | 2.75” Huggers w Hat on Hat- Panel Fixity | Vertical SSR Rib Panel- Hip Detail |

| Generic- High Eave- Vented | 2.75” Huggers w Integral Sub-Rafters- Zone Grid | Vertical SSR- Hugger Lap Attachment |

| Generic- Hip Cross Section | Trapezoidal SSR over Vertical SSR- High Eave | Vertical SSR over Vertical SSR- Hugger Attachment |

| Generic- Lean To Step Detail | Trapezoidal SSR over Vertical SSR- Hugger Attachment | Vertical SSR over Vertical SSR- Hugger w Tab Attachment |

| Generic- Low Eave Detail | Trapezoidal SSR over Vertical SSR- Hugger w Tab Attachment | Vertical SSR over Vertical SSR- Low Eave |

| Generic- Ridge Non-Vented Detail | Trapezoidal SSR over Vertical SSR- Low Eave | Vertical SSR over Vertical SSR- Rake End Wall |

| Generic- Ridge Vented Detail | Trapezoidal SSR over Vertical SSR- Rake to Wall | Vertical SSR over Vertical SSR- Rake to Wall |

| Generic- Valley Cross Section Detail | Vertical SSR- Huggers w Hat on Hat- Zone Grid | Vertical SSR- Valley Detail |

Existing Corrugated Roof Panels

Roof Hugger parts are designed to fit over this existing panel type. Our Custom Corru-Fit Hugger system is adaptable to the different rib center spacings of these panels. It is also a good choice with an existing 7.2 Rib panel, Mini Rib Panel, “B” Deck, and other various situations that have tight rib spaced panels.

The following files are in the download links:

| Corru-Fit- Ridge Non Vented | Generic Panel over Corru-Fit- Low Eave | Trapezoidal SSR over Corru-Fit- Corru-Fit- Hugger Attachment |

|---|---|---|

| Corru-Fit- Valley Gutter Detail | Generic- Hip Detail | Trapezoidal SSR over Corru-Fit- High Eave |

| Corru-Fit Huggers w Hat on Hat- Zone Grid | Generic- Hip Cross Section | Trapezoidal SSR over Corru-Fit- Low Eave |

| Generic- Valley Detail | R-Panel over Corru-Fit- Corru-Fit- Hugger Attachment | Trapezoidal SSR over Corru-Fit- Rake End Wall |

| Generic- Ridge Vented | R-Panel over Corru-Fit- High Eave | Vertical SSR over Corru-Fit- Corru-Fit- Hugger Attachment |

| Generic- Low Eave Detail | R-Panel over Corru-Fit- Rake End Wall |

do you need engineering included in your quote?

If you are bidding a metal roof retrofit, and you’re not sure if you need to include engineering in the quote, here are a few building situations and locations that will let you know to include engineering.

In the state of Florida, engineering is required on all new metal roofs. Around the country engineering is usually required with all state and local government owned buildings, all schools, military installations, buildings located near open water, or high wind hurricane or tornado zones. Engineering can be required in areas with heavy snow loads too.

Roof Hugger will estimate the wind and snow loads for your project at no charge, if requested. Our proposal will include the material we think is needed to comply with the current building codes. We are not an engineering firm, our third-party engineer handles all finished designs, and our estimated design and pricing will be subject to final engineering review.

how many lineal feet of huggers do you need?

To determine the lineal footage that you may need, use this simple formula:

For a given slope, you divide the width of the slope by the spacing of the existing purlins, and be sure to add 1 for the eave strut. Now multiply that by the length of the eave, and that will give you the lineal footage for that side of the building.

If it’s a mono slope you’re all set, if it’s a gable, you usually can double your answer, however always double check the other sides purlin count.

All other roofs, it’s time to get some paper and draw it out.

NOTE: The new more stringent building code may require the new roof panels to be supported more closely than the existing purlin spacing. This will require additional Roof Hugger framing material. When in doubt check with Roof Hugger before quoting the project.

Roof Hugger Animated Installation Video

This video, of course, is an Artist’s rendered view of how simple Roof Huggers are installed. It illustrates the sequence of installation from installing our sub-rafters that are commonly included for wind uplift conditions in the corners and edges of the roof.

These are not always required, but Roof Hugger will determine their need based on a preliminary design using your chosen new roof system’s E1592 test results. Then the eave Hugger is installed working your way up slope to the primary Huggers over the existing purlins and adding intermediate Huggers between the existing purlins.

Our sub-rafters allow these intermediate Huggers to securely fasten to the new roof’s sub-framing system and satisfy building code required wind requirements. Insulation is installed during the new roof installation process if the building owner and roofing contractor chooses to include it. Installation of a Roof Hugger Metal-over-Metal Retrofit sub-framing system is Safe and Easy to understand.

THE DO'S AND DON'TS OF RETROFIT ROOFING

There are a number of ways that existing metal roofs have been and still are being retrofitted. Many of these methods cannot be considered structurally correct sub-framing systems. They lack the ability to withstand wind uplift and therefore are subject to failure. Roof Hugger sub-framing systems have been installed on over 120 million square feet of existing metal roofs and continue to be installed on approximately 6 million square feet annually.

Our systems have withstood hurricane force wind loads from Katrina, Ike and others without a single failure. This is a testament to our systems that they are safe and structurally correct. This is the primary reason why Roof Hugger is the most specified metal-over-metal sub-framing systems by building owners nationwide including federal and state governments, the military and schools. Below are some of the other methods which we have listed their challenges.

Because of the width of the hat section, only one screw can be installed into the existing purlin. The other screw is attached to the existing 26 to 29 gauge metal, which does not provide sufficient pull-out strength.

Because of the width of the hat section, only one screw can be installed into the existing purlin. The other screw is attached to the existing 26 to 29 gauge metal, which does not provide sufficient pull-out strength.

Sitting on top of the existing ribs requires a long attachment screw and when exposed to thermal movement, they will “rock” back and forth causing fastener back out and ultimate failure.

Roof Huggers provide a positive connection directly to the existing purlins made available by our factory punched and nesting design.

For the same reasons as #1

For the same reasons as #1

Quantity of fasteners for the new metal roof must be increased due to the much reduced pull-out strength into wood, increasing installation labor and material costs.

Pressure treated wood is corrosive when placed in contact with existing and new metal roofs.

If 18 or 22 gauge hat sections are used in lieu of wood, as shown in the above isometric view, these members increase new metal roof fasteners due to low pull-out strength.

Roof Huggers are made from minimum 16 gauge grade 55 steel.

Most coatings are quick fixes that fail to permanently fix the existing roof.

Most coatings are quick fixes that fail to permanently fix the existing roof.

Preparation of the existing roof is vital to the coating’s performance.

They do not comply with new stringent Building Code wind speeds.

Roof Huggers provide you with a new metal roof with a 50-plus year service life.

TPO systems have become popular recently since they are slightly less expensive than Metal over Metal Systems.

TPO systems have become popular recently since they are slightly less expensive than Metal over Metal Systems.

Design and attachment is critical however. In order to meet existing wind loads the TPO must be connected to the existing purlins per the manufacturers approved and tested details. Systems that are attached only to the existing roof panels, will not comply with the codes.

TPO systems must not allow water to accumulate on the roof surface or overloading and potential collapse is possible (see photo).

TPO systems do nothing to add strength to the existing roof to meet the new code requirements for snow drifting they just add weight.

TPO systems have about half the life span of metal roofing systems, making their slight initial cost advantage a very poor investment.

Roof Huggers provide you with a base for a new long-life metal roof that can comply with all new wind and snow loads. Huggers also create a cavity that can be used to add insulation for increasing the buildings energy efficiency.

Read more about TPO systems: http://www.roofhugger.com/docs/ProfessionalRoofingMetalToTheMetal.pdf

Roof Hugger sub-purlins are specifically designed to fit over any existing metal roof system.

Roof Hugger sub-purlins are specifically designed to fit over any existing metal roof system.

They are much faster, less complex and less expensive than removing and replacing an old metal roof.

They can be made to a specific height for adding insulation or removing steps in roofs that have created poor weather tight roof connections.

They can add strength to the existing purlins to overcome the additional weight of the retrofit.

They can be designed to allow the new roof to comply with todays stricter building code requirements.

Roof Hugger is the most tested retrofit sub-framing System available. They are made from high strength 16ga. (0.060 min.), 50 ksi, G-90 Galvanized steel.

They will allow an existing screw-down metal roof to be upgraded to a standing seam roof without a major engineering analysis and upgrading the existing purlin bracing to make up for the removal of the diaphragm strength provided by the old roof panels.

Roof Hugger products are made in the USA

AISI Gravity and Wind Uplift Base Load Testing conducted by Force Engineering & Testing

Discover how Roof Hugger, Inc’s patented “Huggers” can significantly increase the gravity load and wind uplift capacity of your existing metal roof system, in line with changing Building Code design load requirements, as validated by rigorous AISI Gravity and Wind Uplift Base Load testing.

The Trusted Name in Roof Retrofits

Roof Hugger has installed over 120 Million square feet of existing metal roofs

Roof Hugger is the most tested retrofit sub-framing System available and the most specified metal-over-metal sub-framing system for building owners nationwide, including federal and state governments, the military, and schools.

detailed guidelines for the installation of a structural retrofit roof sub-framing system

Learn more about the design and installation of the Roof Hugger Sub Framing system. View full document here.

In addition to simply providing retrofit sub-purlins to its customers Roof Hugger, Inc. was the first to provide certified design tables and testing on, one – piece – notched “Z” sub-purlin retrofit systems.

Get An Estimate

View this quick video that outlines the details we’ll need to provide you with an accurate estimate, ensuring your metal over metal retrofit system matches your existing roof profile.