Roof Retrofit Tips

Mastering Your Roof Retrofit

Roof Hugger Sub-Framing Systems Essential Tips

Roof Retrofit Tips

Mastering Your Roof Retrofit

Roof Hugger Sub-Framing Systems Essential Tips

Roof Hugger sub-framing systems offer safe and structurally correct retrofits for existing metal roofs

They have been installed on over 120 million square feet of roofs and continue to be used on approximately 6 million square feet annually.

These systems have proven their ability to withstand hurricane force wind loads without failure, as demonstrated during storms like Katrina and Ike.

As a result, Roof Hugger is the most specified metal-over-metal sub-framing system for building owners nationwide, including federal and state governments, the military, and schools.

Key Considerations for Effective Roof Retrofitting

Because of the width of the hat section, only one screw can be installed into the existing purlin. The other screw is attached to the existing 26 to 29 gauge metal, which does not provide sufficient pull-out strength.

Sitting on top of the existing ribs requires a long attachment screw and when exposed to thermal movement, they will “rock” back and forth causing fastener back out and ultimate failure.

Roof Huggers provide a positive connection directly to the existing purlins made available by our factory punched and nesting design.

For the same reasons as #1

Quantity of fasteners for the new metal roof must be increased due to the much reduced pull-out strength into wood, increasing installation labor and material costs.

Pressure treated wood is corrosive when placed in contact with existing and new metal roofs.

If 18 or 22 gauge hat sections are used in lieu of wood, as shown in the above isometric view, these members increase new metal roof fasteners due to low pull-out strength.

Roof Huggers are made from minimum 16 gauge grade 55 steel.

Unless the manufacturer of the stand-off clips has a manner to provide required additional sub-framing in the edges and corners of the existing roof, this method is challenged to withstand the increased wind loads in these zones by only attaching to the existing purlins.

Roof Huggers come with additional sub-framing, project engineered to meet wind loads up to and over 155 MPH wind speeds.

Most coatings are quick fixes that fail to permanently fix the existing roof.

Preparation of the existing roof is vital to the coating’s performance.

They do not comply with new stringent Building Code wind speeds.

Roof Huggers provide you with a new metal roof with a 50-plus year service life.

Read more about coatings:

TPO systems have become popular recently since they are slightly less expensive than Metal over Metal Systems.

Design and attachment is critical however. In order to meet existing wind loads the TPO must be connected to the existing purlins per the manufacturers approved and tested details. Systems that are attached only to the existing roof panels, will not comply with the codes.

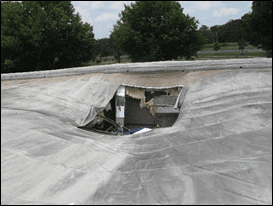

TPO systems must not allow water to accumulate on the roof surface or overloading and potential collapse is possible (see photo).

TPO systems do nothing to add strength to the existing roof to meet the new code requirements for snow drifting they just add weight.

TPO systems have about half the life span of metal roofing systems, making their slight initial cost advantage a very poor investment.

Roof Huggers provide you with a base for a new long-life metal roof that can comply with all new wind and snow loads. Huggers also create a cavity that can be used to add insulation for increasing the buildings energy efficiency.

Roof Hugger sub-purlins are specifically designed to fit over any existing metal roof system.

They are much faster, less complex and less expensive than removing and replacing an old metal roof.

They can be made to a specific height for adding insulation or removing steps in roofs that have created poor weather tight roof connections.

They can add strength to the existing purlins to overcome the additional weight of the retrofit.

They can be designed to allow the new roof to comply with todays stricter building code requirements.

Roof Hugger is the most tested retrofit sub-framing System available. They are made from high strength 16ga. (0.060 min.), 50 ksi, G-90 Galvanized steel.

They will allow an existing screw-down metal roof to be upgraded to a standing seam roof without a major engineering analysis and upgrading the existing purlin bracing to make up for the removal of the diaphragm strength provided by the old roof panels.

Roof Hugger products are made in the USA